[ 发布时间:2018-06-20 阅读:1203次 ]

GD&T Training Group Picture-Jun. 8 in Suzhou

In order to better service our customers and improve our professional skills, we invited Mr. Mike Long, Asia Representative of Tec-Ease, Inc. and held “Geometric Dimensioning & Tolerancing Training” on June 7 and 8 for two days. We invited 50 VIP customers to attend the training.

In order to better service our customers and improve our professional skills, we invited Mr. Mike Long, Asia Representative of Tec-Ease, Inc. and held “Geometric Dimensioning & Tolerancing Training” on June 7 and 8 for two days. We invited 50 VIP customers to attend the training.

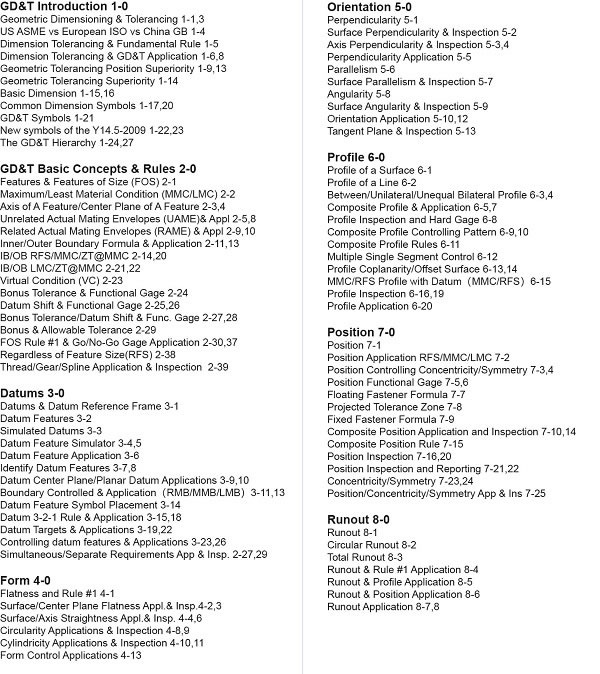

The two days training focused on below topics:

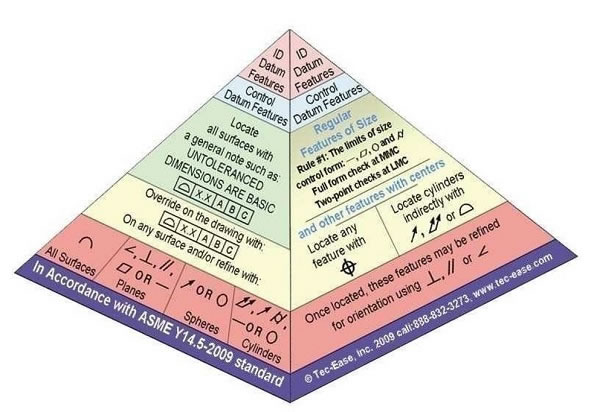

1. US ASME Y14.5M-2009 GD&T basic concepts

2. GD&T symbols, terms, concepts and rules

3. Maximum/Least Material Condition (MMC/LMC), Bonus Tolerance, Datum Shift, ZT@MMC

4. FOS Rule #1, Regardless of Feature Size(RFS) (Rule #2)

5. Controlling datum features & Applications

6. Form, Orientation, Profile, Position, Runout

7. Tolerance Zone

8. Go-No Go Gages & Gage Design

Trainees are those who use GD&T to design, produce and inspect parts as mechanical engineers, designers, managers, production planners, inspectors, machinists, supplier quality personnel, etc.

Training Outlines:

This training was held aiming at high-quality customers of V-Tech Group. The training sharpens trainees’ Geometric Tolerancing skills and provide the trainees with guidelines for selecting the most appropriate inspection methods for inspecting a part feature, low cost functional gage design principles, criteria for selecting company/division gaging policy and an overview of inspection equipment capabilities.

Q&A, discussion was arranged during the training. The teacher communicated fully with the customers, explaining doubts from the customers. Trainees did not only listen carefully, but also attended interaction actively.

Many customers raised doubts and difficulty concerning GD&T, which had been explained in detail by the teacher.

Many customers also gave us valuable suggestions according to this training, which was a most rewarding gain for us to improve our training organization in the future.

We will continue to improve ourselves to meet customer’s needs, returning every customer with excellent quality and service.